Adding Value for Port Clients with Waterfront Engineering, Materials Handling Under One Roof

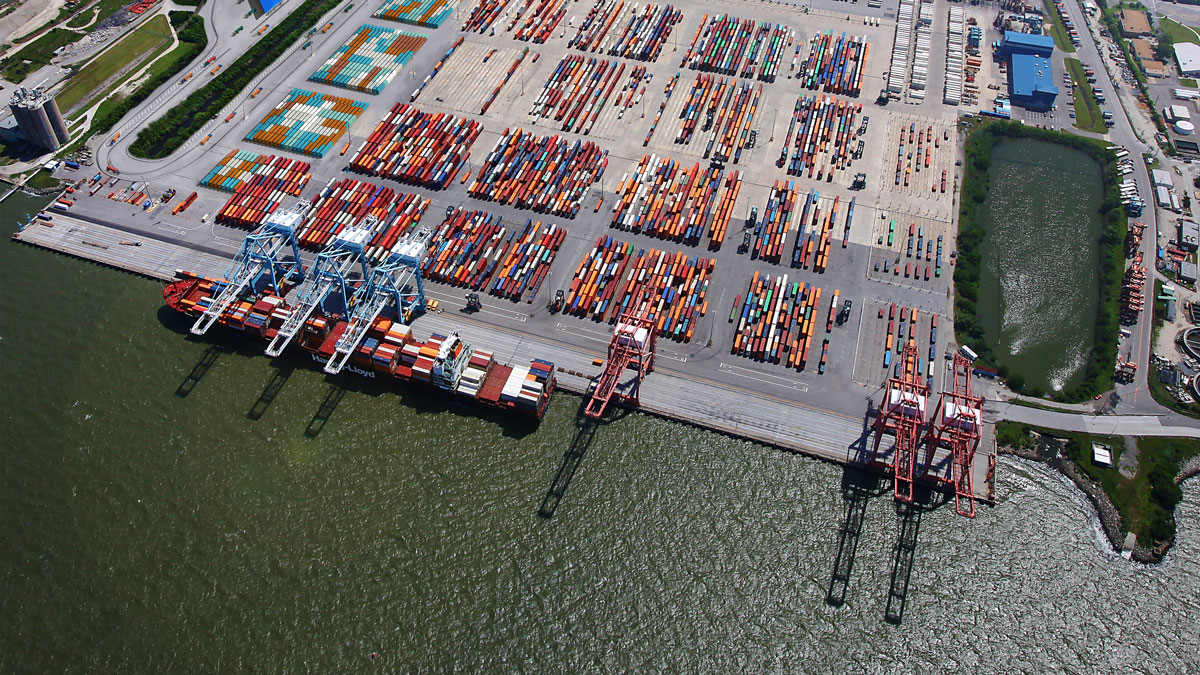

Ports are a critical economic link for their surrounding regions, accommodating the import and export of a wide variety of goods and materials. Having solid waterfront infrastructure, off-loading processes, and warehousing makes a port more appealing to the industries and organizations who rely on maritime transportation.

Ports are a critical economic link for their surrounding regions, accommodating the import and export of a wide variety of goods and materials. Having solid waterfront infrastructure, off-loading processes, and warehousing makes a port more appealing to the industries and organizations who rely on maritime transportation.

Through annual service contracts at multiple ports on the East Coast, our waterfront engineers and industrial mechanical engineers are adding value for port clients by providing a single, cohesive source of specialized expertise. I spoke with Dave Pryor, PE, Clark Nexsen’s Director of Waterfront Engineering, and David Robinson, a Senior Project Manager in our industrial and process engineering practice, to understand what enables us to best serve port clients:

Breadth of expertise – from being full-service to the ability to complete specialized tasks – is Clark Nexsen’s greatest value to port clients.

“It’s rare for a firm to have civil engineering, process engineering, and vertical design expertise under one roof,” Dave shared. “A port can contract with us and have access to expertise in waterfront engineering and bulk and liquid material handling in one firm.”

David Robinson added that there is substantial overlap between projects that might begin on the industrial or materials handling side and require waterfront work. “If we’re designing a materials handling process to receive product from a ship and load it to a warehouse, for example, we may need a new dock or dock extension,” commented David. “A typical materials handling group would need to outsource the waterfront component, which takes time to do, but we can just call our own waterfront team.”

With multiple locations in the Mid-Atlantic and Southeast, Clark Nexsen is positioned to serve East Coast ports exceptionally well. Sometimes, David noted, we join forces on specific projects from the beginning, but most often, our appeal to port clients is the convenience of having a master contract and gaining access to broad expertise. While waterfront engineering and industrial process engineering are high profile needs, our other services add value, too. A good example is our current work with Balfour Beatty Construction to renovate a cold storage facility at the Wilmington, NC port, which has involved architecture and a range of vertical engineering services.

At the Norfolk International Terminal, our civil, structural, and transportation engineers designed improvements to the North Gate Complex that enhance accessibility and efficiency for the port. Improvements include an automated truck gate, heavy-duty paving, and five new buildings including a 16-lane inbound canopy, a 10-lane outbound canopy, inbound and outbound OCR (optical character recognition) portals, and a driver assistance facility.

Breadth of expertise – from being full-service to the ability to complete specialized tasks – is Clark Nexsen’s greatest value to port clients. For example, our industrial team also completes hazard analyses, which can be very useful for port authorities when dealing with warehousing of materials that are classified as hazardous. “For ports that do bulk material handling, it’s one stop shopping,” David concluded. “Clark Nexsen is unique in the scope of what we can offer a port authority.”

Dave Pryor, PE, previously led our Waterfront practice, specializing in marine structures, coastal engineering, shipbuilding, and management. He left the firm in 2023.

David Robinson is a senior project manager in our Industrial practice with a substantial background in bulk materials handling and the pulp and paper industry. David established our Brunswick, GA office in 2005 to serve industrial clients in the coastal regions of GA and FL. To learn more or to speak with David, please call 912.805.3155 or email drobinson@clarknexsen.com.